Grading hardwood for floors

Grading

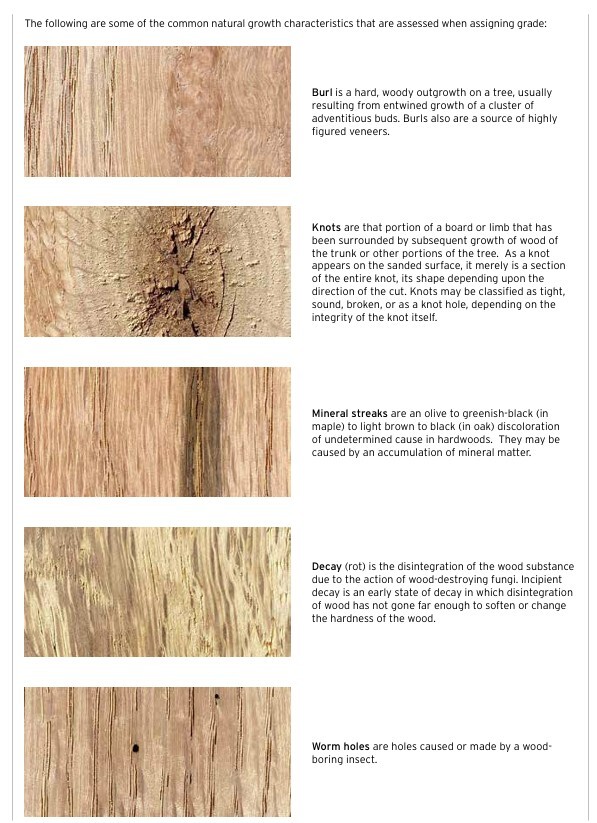

Among the many qualities that influence the appearance of wood flooring is the grade of the wood. The tree from which lumber and flooring is obtained is a product of its environment, which includes varying combinations of the soil, moisture, air, and sunshine that it is exposed to through its life. The tree also is subjected to extremes of temperature, wind, floods, insect infestations, drought, and injury. As a result, wood varies in structure and in appearance. In addition, further characteristics develop through the process of manufacturing and drying. All of the aforementioned characteristics are what differentiate one grade from another. Sawn hardwood lumber is graded to provide categories for the wood that is processed, to determine the value, waste factor, and potential use, for each board of sawn lumber. The National Hardwood Lumber Association (NHLA) established grading standards for the hardwood lumber industry in 1898. The NHLA grading rules provide consistent language, based on the percentage of clear wood in each board, to identify and categorize it based on its aesthetic characteristics. These rules originally were designed with the furniture trade in mind to provide a measurable percentage of clear, defect-free wood for each grade. Much of the wood flooring industry manufacturers purchase sawn lumber to produce wood flooring. Wood flooring is graded to a minimum standard that describes the extent and limitations of the characteristics permitted in a piece of flooring. Similar to sawn lumber, the purpose of flooring grading is to sort wood flooring into groups with similar characteristics. Since no two pieces of flooring are identical, complete uniformity in grades or shipments is impossible. Appearance alone determines the grades of hardwood flooring since all grades are equally strong and serviceable in any application. All characters included in a higher grade are automatically accepted in lower grades. Wood flooring grading rules specifically identify frequency, size, and number of some common characteristics.

Grading is an essential part of doing business in the hardwood flooring industry. Grades group flooring with similar qualities, bringing a degree of consistency to products from different mills. Grades give the purchaser information about what they should expect when buying wood flooring products, including surface characteristics, required lengths, and milling tolerances. All wood flooring should conform to its grade description. There is a general allowance of not greater than 5% of the pieces that may be off grade. In some cases, grades are established by industry associations, such as NWFA/National Oak Flooring Manufacturers Association (NOFMA), established in 1909, and Maple Flooring Manufacturers Association (MFMA), established in 1897. The development of hardwood flooring grades was the main impetus in

the formation of those groups in the early 1900s. The NWFA/NOFMA grading system has become such a wellestablished tradition in hardwood flooring production, even mills that are not members of the NWFA or participants with NWFA/NOFMA certification routinely separate their production along NWFA/NOFMA grading guidelines. In addition to using standard flooring grades such as those developed by NWFA/NOFMA and MFMA, many flooring manufacturers have their own proprietary grading standards. There are various reasons for this; some grade names are more marketing-friendly; others wish to be either more specific, or more general, than the industry standards; some may have been created in response to a void in a specific product or species. Most industry wood floor grading standards also include configuration guidelines such as width, thickness, match-position, match-fit, overwood, moisture content, board length, square footage, and packaging.